Independent Suspension system

Independent Suspension systems

are commonly used in the front axle. When a wheel climbs a bump, the other wheel will travel in its own path.Hence,the vibration will not be transmitted from one wheel to another which leads to smooth ride to the passenger.

Types of Independent front suspension system

1. Wishbone or Parallel link type.

2. Vertical guide type

3. Trailing link type

4. Macpherson strut type

5. Swing half axle type.

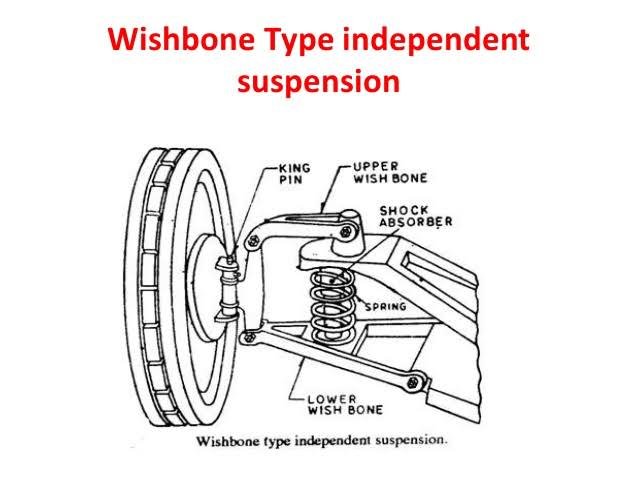

Wishbone suspension system

This type of suspension system is often used for front wheels. In this

This type of suspension system is often used for front wheels. In this

system, two arms namely upper wishbone arm and lower wishbone arm are used. The upper wishbone has a short arm and lower wishbone is a long arm and it is connected with the frame. Vibration damper and coil spring are fixed over the rubber pad in between the lower wishbone. arm and fixed cross member. Wishbone Arms keep the wheel in its position and transmit the load to the spring. Therefore, the tractive force,

brake force and lateral force get absorbed. Due to the shortened length of the upper arm the tire wear gets reduced.

Special Features

1. Since length of upper wishbone is shorter than the lower wishbone, wheels are slightly inclined. This leads to no slip in the tyre and the wheel track does not change and hence the tyre wear is reduced.

2. The two wishbone arms help in

positioning the front wheels and they

withstand the braking torque while

braking.

3. There is no effect on one wheel while other wheel travels through ups and downs in the road.

Vertical guide suspension system

It is the first developed independent front suspension system. In this suspension the kingpin is directly

It is the first developed independent front suspension system. In this suspension the kingpin is directly

attached to the cross member of the frame and spacing rod. The coil spring is fitted as shown in the figure.

When the wheel travel over the

bumpy road, spring compress or expands and this makes the stub axle to slide up and down. In this type, caster angle, camber angle and wheel direction are remained unchanged as the wheel moves up and down.However, the disadvantage

is less strength.

Notes

1. While the vehicle running, the sliding member is also moving up and down. Therefore, the spring gets compressed and elongated continuously.

2. When the specific wheel going through up and down, the sliding member is also moving up and down. However,the castor and camber angle will not change.

3. This is system cannot be used because of its less strength.

4. The efficiency of the system is based on the sliding member movementnaccuracy.

5. It is difficult to avoid the shock and

less holding that can occur.

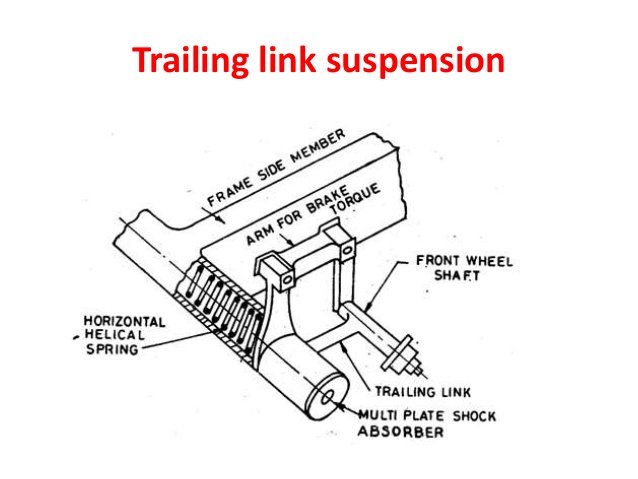

Trailing link types

Construction

In this type of suspension system, coil

springs are positioned between cross

member and the trailing link. On the

other side of the trailing link, wheels are fixed. In some vehicles, torsion bars are used instead of horizontal coil spring.

Working principle

When the vehicle wheel passing over

When the vehicle wheel passing over

the bumps and pits, trailing arm oscillates like a springboard. The road disturbance is absorbed by spring deflection. Multiplate shock absorber is used to dissipate the stored

energy in spring. This type of suspension system usage is very limited in vehicles, it is because of the maintenance and repair of this suspension system are complex in nature.

Mac Pherson Strut types

It is widely used in the front suspension vehicles. The MacPherson

It is widely used in the front suspension vehicles. The MacPherson

Strut type suspension system consists of with a telescopic strut and a single

arm along with a diagonal stay. Lower

Wishbone arm is alone available in this system. Shock absorber and spring areacting as an integrated unit known as strut. Stub axle support the strut and stub axle hold the wheel.

When the vehicle wheel moves

over the bumps and pits, Camber angle remains unchanged. It provides more amount of space to mount engine.Hence, this is most widely used in front wheel drive vehicle like Maruthi 800, Hyundai.

Advantages

1. Simple in construction

2. Minimum number of parts

3. Ease of maintenance

Swing half axle types

Wheels are firmly fixed on one end of the half axle and the other end of the half axle is fixed to the center

Wheels are firmly fixed on one end of the half axle and the other end of the half axle is fixed to the center

point of the chassis frame. Coil spring and shock absorber are mounted as shownnin the figure. When the wheel passes thenbumps and pits, axle get oscillates. As thenvehicle moves on the irregular roads, coil spring and shock absorber are stretchednor compressed simultaneously to take thenroad disturbances.

Rear axle independent suspension system

Rear axle independent suspension

system construction is given in the

figure. In most of the vehicles, the drive from the engine is given to

the rear wheels. Hence it is difficult

to design, constr uct and installing

an indep endent susp ension system

In rear wheel drive vehicles . The

differential unit is firmly fixed on

the chassis cross frame member. Two universal joints (A & B) are there in between differential unit and wheel,

movable coupling (C) allows to move

up and down motion of the wheel.

A shock absorber is incorporated to

the system. With the help of thes e

components, the system absorb the

ro ad disturb ance w hen t he vehicle

passes over the bumps and pits.